I quit playing with the new toy (3D Printer) long enough to populate and test the AF amplifier section of the SMD BITX.

As you can see even though it is built with mostly SMD components, the layout is much larger than it really needs to be. But since I plan on putting it in an old CD drive case there was no real reason to shrink it down any more. I do have another project in the very early stages that shrinks a transceiver down a lot more.

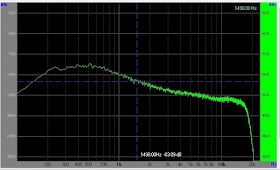

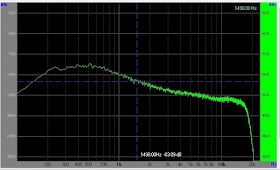

After getting the AF stages built, it sounded good with a low level test signal injected, no hiss or background noise. But, I decided to test it to see what the output response looks like. I connected up my sound card based audio spectrum analyzer-signal generator, and started the Visual Analyzer program. I didn't bother calibrating the input level, so values are just relative for measuring stage gain.

With everything connected but the signal generator turned off and the Volume pot all the way up I had a fairly flat baseline out to over 16Khz. that had a value of about -115 dB at around 1500 Hz. Not sure where the 1 Khz. spikes are coming from, probably from something in the computer. But after applying the pink noise signal I could not see them in the output at any volume setting.

After getting the AF stages built, it sounded good with a low level test signal injected, no hiss or background noise. But, I decided to test it to see what the output response looks like. I connected up my sound card based audio spectrum analyzer-signal generator, and started the Visual Analyzer program. I didn't bother calibrating the input level, so values are just relative for measuring stage gain.

With everything connected but the signal generator turned off and the Volume pot all the way up I had a fairly flat baseline out to over 16Khz. that had a value of about -115 dB at around 1500 Hz. Not sure where the 1 Khz. spikes are coming from, probably from something in the computer. But after applying the pink noise signal I could not see them in the output at any volume setting.

After turning on the pink noise generator and averaging the signal, the amplitude at the same frequency increased to -83 dB, a 32 dB gain at 1.5Khz. The maximum gain was around 500 Hz. with a gain of 39 dB. The 6dB response is from about 200Hz. to 1.2 Khz. The higher frequency response is more than I would like, but I will live with it for now. If I start hearing a lot of hiss after I get more stages built, will see about changing the response.

Next to build and test the microphone amplifier. Then I will have to get one of the early si5351 VFO test circuits I built a couple of years ago modified to work as a test VFO and BFO.

Now I NEED to get back and play with the new toy some more.

After turning on the pink noise generator and averaging the signal, the amplitude at the same frequency increased to -83 dB, a 32 dB gain at 1.5Khz. The maximum gain was around 500 Hz. with a gain of 39 dB. The 6dB response is from about 200Hz. to 1.2 Khz. The higher frequency response is more than I would like, but I will live with it for now. If I start hearing a lot of hiss after I get more stages built, will see about changing the response.

Next to build and test the microphone amplifier. Then I will have to get one of the early si5351 VFO test circuits I built a couple of years ago modified to work as a test VFO and BFO.

Now I NEED to get back and play with the new toy some more.

I have been interested in getting a 3D Printer for some time now, and a couple of months ago I bought a kit from a supplier on eBay. There is a fairly active Facebook group dedicated to this printer, so I thought it would be the one to try. After starting assembly, I found that it would be a little larger than I had room for on my work desk, and would have to be moved around when I wanted to use it. So it kind of sits, mostly assembled while I am working on some other projects.

I was browsing for something else on eBay and checked out the 3D printers, and found the Cube generation 3 printer for under $200 including shipping. This is made by 3D Systems, one of the larger players in the 3D printing market. I had looked at this printer before, and it had been selling at around $1000.

3D Systems Cube gen 3 Printer I checked their web site, and saw that this model had been discontinued, but they said they are still supplying the print cartridges.

I looked at several other places such as Amazon, and found that they were also selling it for about $250. Sounds like a close out deal, so I decided to get one from one of the eBay sellers for $180 shipping included. I was surprised when it was delivered in 3 days.

It came in what must be the original double boxing.. Unpacking and setup took less than a half hour. I really like its small size, less than 14"x14"x10" and it fits on my desk with no problem. This is a two color printer, and uses cartridges instead of spools of filament. This helps keep the overall size down.

You can copy prints to the printer using either a supplied USB stick or with the built in WiFi, I tried both and they work well. I setup the WiFi connection using the small touch screen display on the printer, and then downloaded and installed the Cube -Print program on my PC, and ran through the activation. I ran the calibration and auto bed leveling routines using the setup functions through the touch screen on the printer. The test print turned out well, so I downloaded one of the free projects that 3D Systems has available. That also printed well, so I decided to get a project from Thingiverse.

I downloaded a small spinner knob for a rotary encoder, and loaded it into the Cube-Print program and tried to print. I got a message about needing to update the firmware on the printer. I did a quick firmware down load from the 3D Systems website and transferred it to the printer on the USB sick. Using the update routine in the printer

Settings, it only took a few minutes to update the firmware. I tried the print again, and it turned out very nice. I downloaded and printed a couple other projects and was pleased with the results I got.

Next I setup an account at OnShape , a free web based 3d Cad program. After a little playing around I was able to design a simple bezel for the 1.4" display I used in several projects. The print results are usable, but I will probably refine the design a little later.

The picture shows the bezel and one of the other knobs just sitting on the top of the AD8307 Power meter. My printer came with White and Green PLA filament cartridges, and just ordered Black ABS cartridge to try.

So far I am very pleased with the printer. Mechanically it is very well built, under the plastic shell is a solid metal framework. It uses linear slide bearings instead of the rods and slides used by most of the kits. The built in alignment routines are very easy to use, and from what I can tell work quite well. It does not have a heated bed, instead uses a water soluble glue that you have to apply to the bed before use. I have only tried with PLA, but so far it seems to work well. Will see how it works with ABS when the cartridge I ordered arrives. The build area is 6"x6"x6" which should be large enough for anything I want to do.

The cartridge system with the print nozzle and filament feed mechanism seem to work well. This is more much expensive than using bulk filament if you do a lot of printing. I have seen a couple things on You Tube showing ways to use bulk filament, so will give them a try when I use up one of the original cartridges that came with the printer.

So far I am very happy with the printer. This is about the cheapest and easiest way to give 3D printing a try that I have found. So if you want to try I don't know how long the supply of these printers will be available for the price they are going for now. I will let you know how everything goes after a little more use. But now I just started a print job that should take about 7 hours, so I might get back to some of the other projects I have going.

I downloaded a small spinner knob for a rotary encoder, and loaded it into the Cube-Print program and tried to print. I got a message about needing to update the firmware on the printer. I did a quick firmware down load from the 3D Systems website and transferred it to the printer on the USB sick. Using the update routine in the printer

Settings, it only took a few minutes to update the firmware. I tried the print again, and it turned out very nice. I downloaded and printed a couple other projects and was pleased with the results I got.

Next I setup an account at OnShape , a free web based 3d Cad program. After a little playing around I was able to design a simple bezel for the 1.4" display I used in several projects. The print results are usable, but I will probably refine the design a little later.

The picture shows the bezel and one of the other knobs just sitting on the top of the AD8307 Power meter. My printer came with White and Green PLA filament cartridges, and just ordered Black ABS cartridge to try.

So far I am very pleased with the printer. Mechanically it is very well built, under the plastic shell is a solid metal framework. It uses linear slide bearings instead of the rods and slides used by most of the kits. The built in alignment routines are very easy to use, and from what I can tell work quite well. It does not have a heated bed, instead uses a water soluble glue that you have to apply to the bed before use. I have only tried with PLA, but so far it seems to work well. Will see how it works with ABS when the cartridge I ordered arrives. The build area is 6"x6"x6" which should be large enough for anything I want to do.

The cartridge system with the print nozzle and filament feed mechanism seem to work well. This is more much expensive than using bulk filament if you do a lot of printing. I have seen a couple things on You Tube showing ways to use bulk filament, so will give them a try when I use up one of the original cartridges that came with the printer.

So far I am very happy with the printer. This is about the cheapest and easiest way to give 3D printing a try that I have found. So if you want to try I don't know how long the supply of these printers will be available for the price they are going for now. I will let you know how everything goes after a little more use. But now I just started a print job that should take about 7 hours, so I might get back to some of the other projects I have going.

After getting the AF stages built, it sounded good with a low level test signal injected, no hiss or background noise. But, I decided to test it to see what the output response looks like. I connected up my sound card based audio spectrum analyzer-signal generator, and started the Visual Analyzer program. I didn't bother calibrating the input level, so values are just relative for measuring stage gain.

After getting the AF stages built, it sounded good with a low level test signal injected, no hiss or background noise. But, I decided to test it to see what the output response looks like. I connected up my sound card based audio spectrum analyzer-signal generator, and started the Visual Analyzer program. I didn't bother calibrating the input level, so values are just relative for measuring stage gain.  After turning on the pink noise generator and averaging the signal, the amplitude at the same frequency increased to -83 dB, a 32 dB gain at 1.5Khz. The maximum gain was around 500 Hz. with a gain of 39 dB. The 6dB response is from about 200Hz. to 1.2 Khz. The higher frequency response is more than I would like, but I will live with it for now. If I start hearing a lot of hiss after I get more stages built, will see about changing the response.

After turning on the pink noise generator and averaging the signal, the amplitude at the same frequency increased to -83 dB, a 32 dB gain at 1.5Khz. The maximum gain was around 500 Hz. with a gain of 39 dB. The 6dB response is from about 200Hz. to 1.2 Khz. The higher frequency response is more than I would like, but I will live with it for now. If I start hearing a lot of hiss after I get more stages built, will see about changing the response.